Elstein HTS Series High Temperature Ceramic Heaters

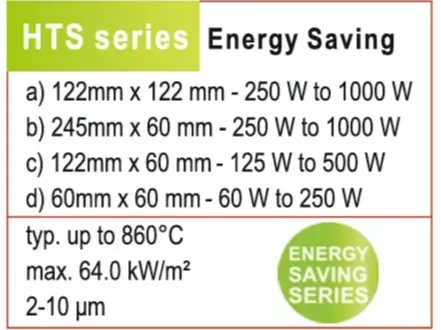

Elstein HTS High Temperature Heaters are ceramic infrared panel heaters designed for operating temperatures up to 900°C and surface ratings up to 64 kW/m². They are produced using a hollow-casting ceramic process and are filled with thermal insulation material. This design improves the radiant power output to the material being heated and significantly reduces heat dissipated in the wiring space. Compared to heaters made with a full-poured casting process, HTS heaters have a considerably reduced heating-up time and can enable energy savings of up to 25%, depending on the application.

Key Features

- Operating temperatures up to 900°C

- High surface power rating (up to 64 kW/m²)

- Improved radiant power output, maximizing heating efficiency

- Significantly reduced heat dissipation in wiring space

- Faster heat-up time compared to full-pour casting methods

- Potential energy savings up to 25% depending on application

Common Applications

Subscribe to Our Newsletter

Get the latest industry news, product announcements, and exclusive offers delivered straight to your inbox.